The Tropic, a brewery in Waterbury with some exceptional brews, has been gearing up to start sending kegs out into the world.

Needing some tap handles that match their image and branding, they reached out to me to see if I could help.

After some discussion, I suggested a specific construction we could try that would be relatively affordable. They gave me this sketch to work from.

This is a computer rendered image of the design to help show what the final product will look like. This is an important step to avoid design errors in the prototype.

This design is centered around laser cut aluminum sheets. Laser cutting is an affordable process that scales well.

The laser cut sheets are assembled with a number of shop-made spacers and blocks.

A stencil is used to apply the lettering.

The next step is to produce a prototype. It isn’t just the product being prototyped; this will also test the chosen manufacturing processes and reveal any process problems.

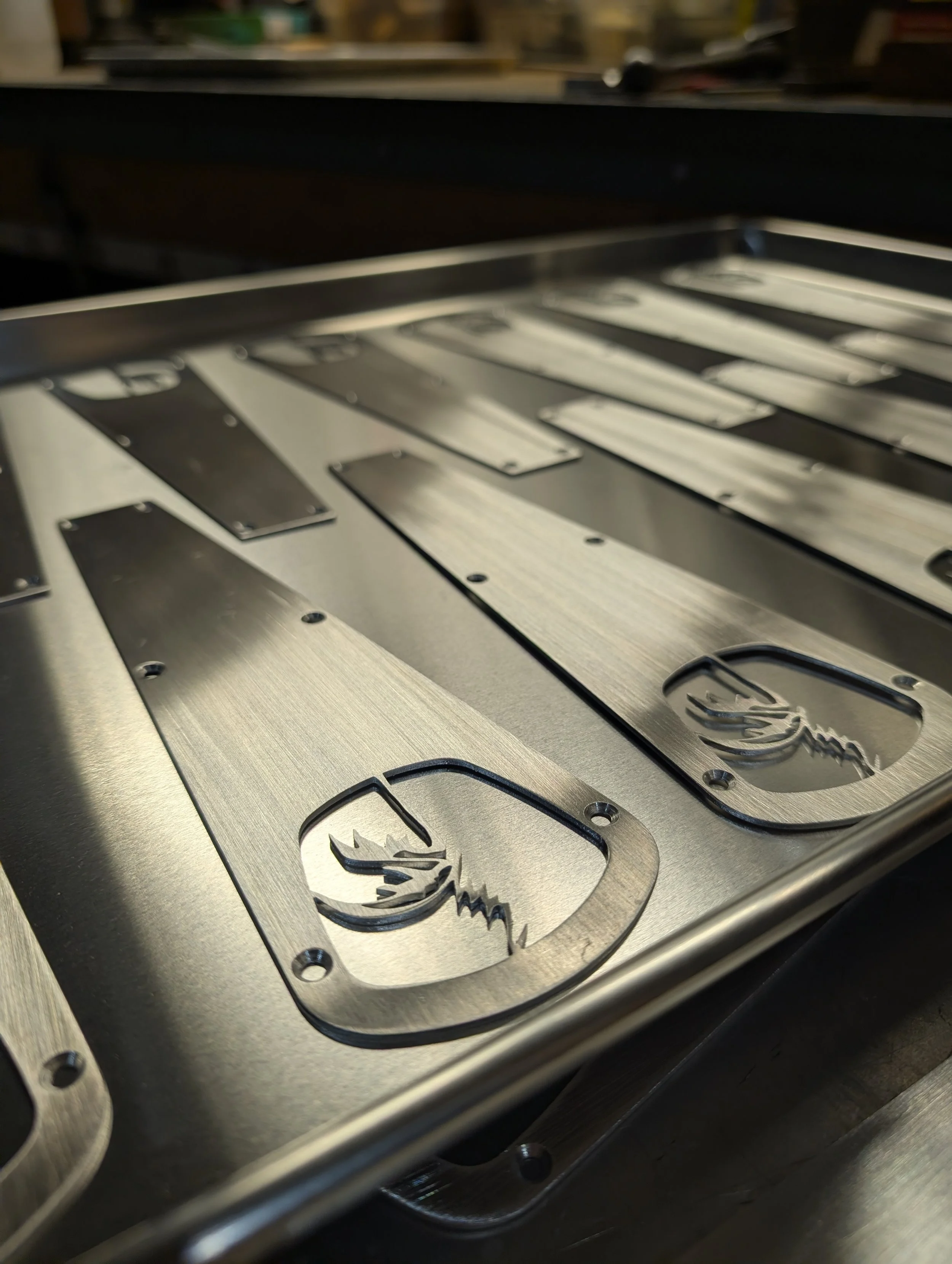

This is the first batch of parts received by the laser cutting contractor.

Included are the front and back plates, the center plate, as well as two sets of stencils.

One stencil will be used for the tap handles; another will be used to put their logo on their kegs.

When manufacturing parts at small volumes, oftentimes it is cheaper to modify a mass-produced product than to make it from scratch.

This is one such example. There is a threaded spacer required that the screws thread into.

To cut this from scratch would be very time consuming. Instead, I chose an “unthreaded” spacer that has the correct length and diameter and simply added threads to it.

With the spacers and plates finished, stenciling the lettering onto the front and back plates is next. A couple of 3D printed parts makes this process faster and more accurate.

With the prototype complete and the customer happy, I ordered the materials to manufacture more. If you’re local to or visiting Central Vermont, you might just see one at a local pub!

Finished parts!